When to Upgrade, Retrofit, or Replace Your Cut-to-Length Line

At VX LLC, we speak with manufacturing professionals every day who rely on their cut-to-length (CTL) lines to deliver precise, high-volume sheet metal for downstream fabrication. Whether you're processing hot-rolled steel for the construction industry, high-strength coil for automotive components, or aluminum for HVAC systems, your CTL line is important in meeting production schedules and quality standards.

But like any industrial equipment, CTL lines age and eventually, performance starts to decline. When that happens, facility managers and plant engineers face a crucial decision: do you upgrade, retrofit, or replace?

Making the wrong choice can lead to excessive downtime, wasted investment, or missed production targets. Making the right one can extend the life of your line, unlock higher throughput, and increase profitability.

Here’s how to evaluate your current equipment and choose the path that makes the most sense for your operation.

When a Workhorse Starts to Stall

For many plants, CTL lines are legacy systems. They may have been installed 10, 20, or even 30 years ago. That kind of longevity speaks to their durability, but no machine lasts forever without attention.

You might begin noticing small issues: sheets coming out slightly short, the line stalling during feeding, or inconsistent stacking. Then come the larger signs: unplanned outages, costly repairs, longer setup times, or safety concerns flagged by inspectors or your team. If your maintenance department is cannibalizing old parts or constantly sourcing obsolete components, that’s a flashing red light.

Worse still, these issues often compound during peak demand seasons. A service center handling just-in-time deliveries to a construction site or auto plant can't afford a line that’s unpredictable.

At this point, the real question isn't if you should act, but how.

When the Core Is Solid, But the Brain Needs an Update

For many facilities, upgrading the CTL line’s control system is the fastest, most cost-effective way to breathe new life into old equipment.

Older lines often rely on outdated PLCs, hardwired relays, or analog controllers that lack the precision and flexibility modern production demands. You might have good mechanics, a strong frame, a solid shear, and a dependable leveler. Still, the control system can’t maintain cut tolerances, handle frequent changeovers, or alert operators to problems fast enough.

A modern control system upgrade can deliver tighter length accuracy, better repeatability, and new safety interlocks. It also enables you to integrate automation features, such as touchscreen HMIs, automatic length presets, production reporting, and even remote diagnostics.

Upgrades also tend to involve the least disruption. In many cases, the new controls can be installed over a scheduled maintenance weekend, meaning you're back up and running before your next shift.

Fix What’s Failing, Keep What’s Working

If your issues go beyond controls, such as your leveler struggling to flatten AHSS coil or your shear jamming under higher gauge demands, a targeted retrofit may be the right fit.

Retrofitting involves replacing or rebuilding one or more core components, such as swapping in a new precision leveler, upgrading the shear, reworking the stacker, or enhancing the material handling system. This approach gives you the performance boost you need without the cost or downtime of a complete line replacement.

Let’s say you're a Tier 2 automotive supplier working with thicker, higher-strength coil than your original line was designed to process. Instead of replacing the entire CTL line, retrofitting a new leveler with more robust backup flights and servo adjustments could immediately improve flatness and reduce scrap without needing to remove the rest of your line.

Retrofitting is also ideal when space is limited or when your floor layout is already optimized around your existing equipment. The new modules can be integrated with minimal footprint changes and tailored to your throughput targets.

The key to a successful retrofit? Integration. It’s not just about hardware; it’s about ensuring the new components work seamlessly with existing drives, sensors, and control logic. That’s where expert planning and support, like what we offer at VX LLC, make all the difference.

When the Only Way Forward Is a Fresh Start

There comes a point when a CTL line is simply past its prime. It may be too slow, too unreliable, or unable to handle the widths, thicknesses, or material types your customers now demand. At that point, investing in a brand-new or pre-owned line becomes the strategic choice.

Replacing your CTL line opens up new capabilities. You can increase throughput, improve safety compliance, expand the material range, and incorporate features that weren’t available a decade ago, such as continuous decoiling, inline printing, or flying shears for high-speed operations.

Yes, the upfront cost is higher. But the long-term benefits, lower scrap rates, less downtime, increased automation, and happier customers, can make it well worth it.

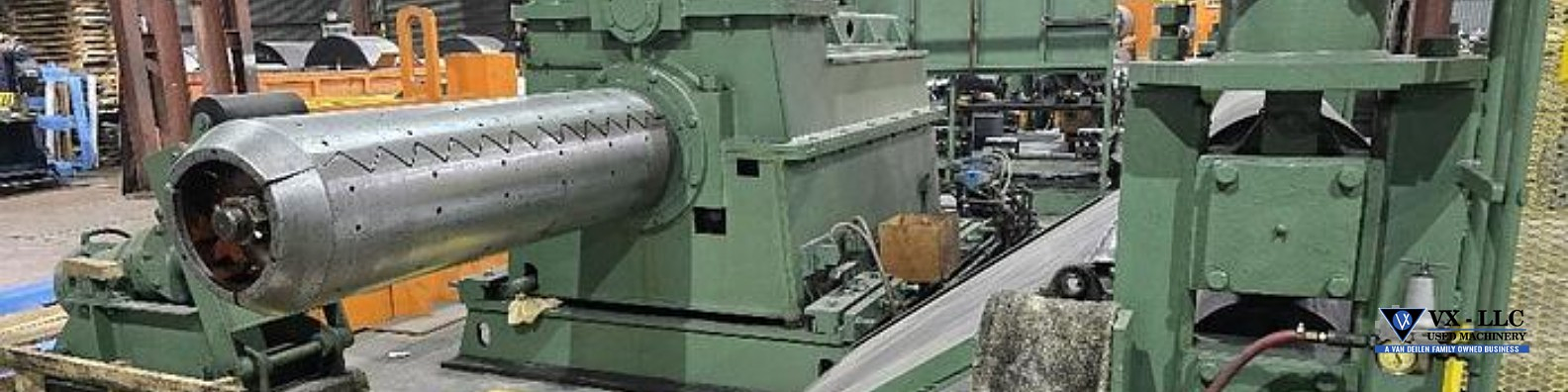

And here’s something many facility managers overlook: replacement doesn’t have to mean “brand new from the OEM.” At VX Machinery, we source and refurbish high-quality pre-owned CTL lines that deliver like-new performance at a fraction of the cost and lead time. Some are ready for shipment and can be installed within weeks, not months.

That’s a huge advantage in today’s market, where custom-built equipment may take 9–12 months or more to deliver, and where global supply chain delays can add even more uncertainty.

Making the Decision

When helping our clients decide between upgrade, retrofit, or replacement, we always ask the same four questions:

- What’s the current cost of doing nothing? - Are you losing production hours? Facing customer complaints? Spending more on maintenance than you should?

- How long do you plan to stay in your current facility or product mix? - If you’re shifting production lines, adding new materials, or expanding into new contracts, your equipment needs to be able to support that growth.

- What’s your downtime tolerance? Some fixes can be made in a day or two. Others require weeks or months of planning. Understanding your production windows helps guide what’s feasible.

- What’s your budget, and what’s the ROI? - A smart investment pays for itself. That might mean a $ 75,000 controls upgrade that eliminates $ 10,000 per month in lost output, or a $ 250,000 replacement that unlocks a new product line.

Why Work with VX LLC?

At VX Machinery, we don’t believe in one-size-fits-all solutions. We help you evaluate your current line honestly, review performance data, and match you with the right upgrade, retrofit, or replacement option.

We offer:

- Full assessments of your CTL line’s mechanical and electrical condition

- Refurbished and pre-owned machinery with verified specs and real-world reliability

- Guidance on budgeting, lead times, and plant integration

- Connections to experienced installers and control system integrators

We’re not here to sell you the biggest, most expensive machine. We’re here to help you make the decision that’s right for your business.

If your cut-to-length line is slowing you down—or you're planning for future growth—let’s talk. We’ll help you decide whether upgrading, retrofitting, or replacing makes the most sense for your operation.

Call VX LLC at (734) 854-8700, email us at info@vxmachinery.com, or send us a message!