Why Pre-Owned Equipment Delivers Big on ROI

In industrial manufacturing, it’s no secret that capital expenses can quickly become excessive. New industrial machinery comes with a substantial price tag, long lead times, and a return on investment that can take years to materialize. But what if there were a smarter, quicker, and more budget-friendly way to grow your operation without compromising performance?

At VX Machinery, we believe there is, and the numbers back it up.

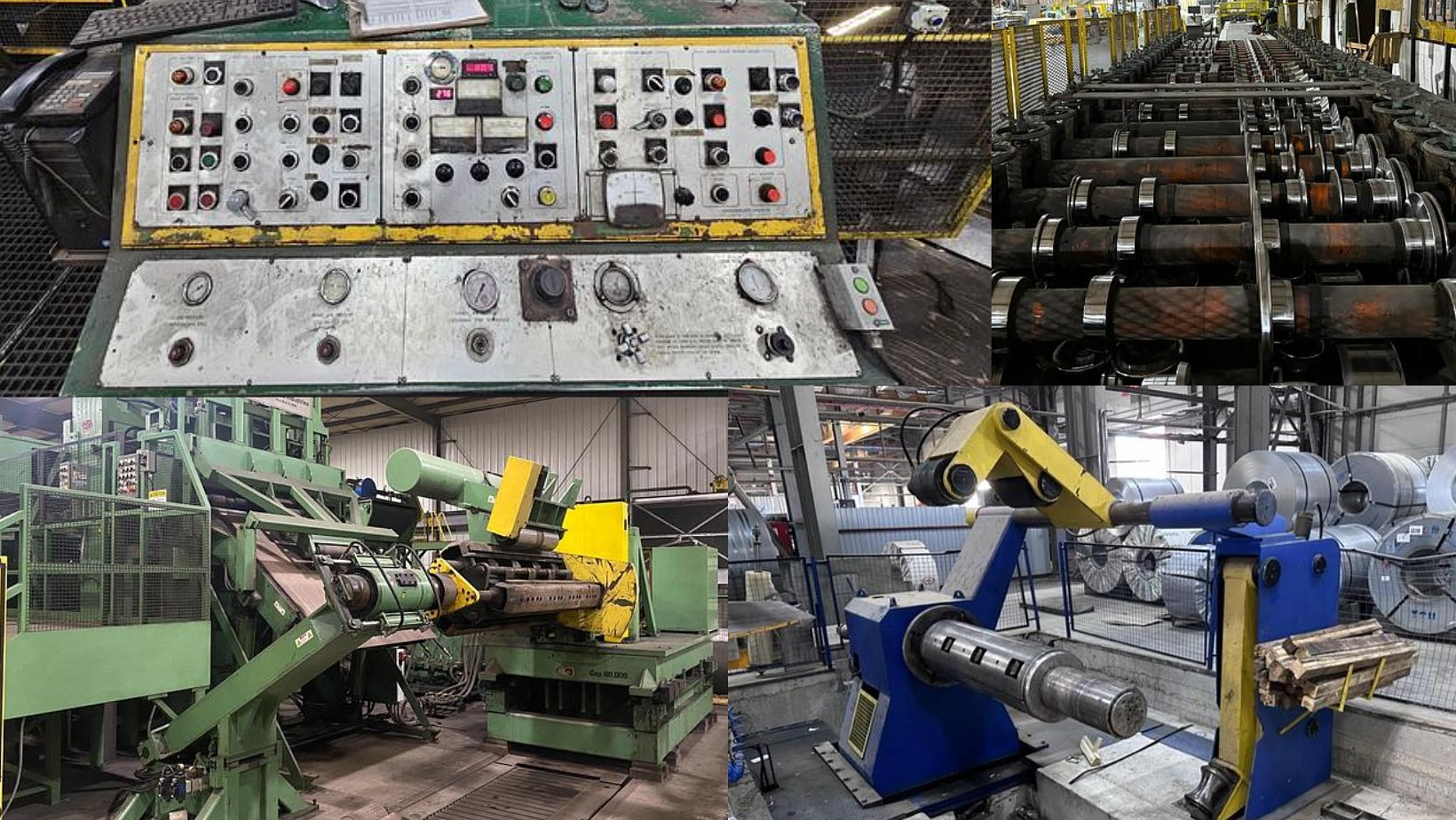

The ROI benefits of buying high-quality used coil processing equipment are simply too compelling to overlook when comparing used vs. new machinery.

Paying Less, Earning More

Used industrial machinery typically costs 50% to 70% less than comparable new models. That’s not just a line item on a balance sheet, it’s a shift in how fast your investment can start working for you. When you shave hundreds of thousands (or even millions) off your equipment costs, you reduce the revenue needed to recoup your spend. In other words, your ROI clock starts ticking much sooner.

For plant managers trying to stretch a tight budget across multiple priorities, used coil processing equipment can be the difference between launching a new line now versus waiting another fiscal year. Whether it's a cut-to-length line, flattener, or rolling mill, you can often acquire what you need at a fraction of the cost of new and still hit your production targets.

Why Lead Time Matters

Why is lead time such a big deal? Because in manufacturing, every delay costs you, whether it’s missed deadlines, stalled projects, or lost revenue. New machines often come with long wait times, sometimes six to twelve months, which can slow down your entire operation. Used industrial machines, on the other hand, are usually available right away. You can inspect, purchase, and have a machine delivered and installed in just a few weeks.

Here’s how that faster lead time works in your favor:

- Keeps your production on schedule – No long delays waiting for equipment to arrive.

- Let's you act on new opportunities quickly – Take on urgent jobs or scale up without the wait.

- Boosts your cash flow faster – Start generating revenue while others await shipments.

- Minimizes costly downtime – Quickly replace failing equipment before it slows you down.

Performance That Holds Up Under Pressure

You might assume “used” means lower performance, but that’s not necessarily true. Industrial machinery is built to last. With proper maintenance, even a ten- or fifteen-year-old machine can still run with incredible reliability and output. Many manufacturers retire machines long before performance declines, often to upgrade technology or comply with new internal policies. The result? A healthy market of gently used equipment that can handle demanding production cycles.

And if you're still worried about technology gaps, here’s the good news: retrofitting is easier and more cost-effective than ever. Modern controls, automation, and safety features can upgrade many older machines. So you get the core reliability of a proven system, with the functionality of something much newer.

Dollars and Sense

Let’s run the math. A brand-new cut-to-length line might run you $2.5 million with a six-month lead time. A used machine in excellent condition might cost under $1 million and be delivered in 30 days. That’s an instant savings of over $1.5 million and a five-month head start on production. You're still way ahead of the game, even assuming some minor retrofit costs or setup expenses.

More importantly, you begin generating revenue sooner, and because you invested less up front, the break-even point comes quicker. In many cases, companies that go the used route reach ROI in half the time compared to new purchases. And if you ever decide to sell or trade in that machine, it’ll hold more of its value than a new one, heavily depreciated.

Sustainability with a Business Edge

Sustainability isn’t just good for the planet, it’s smart business. Choosing used equipment helps extend the life of high-value machinery, which means fewer resources are used to manufacture new ones and less waste ends up in landfills. It also reduces the carbon footprint tied to production, packaging, and shipping. Buying pre-owned machinery is an easy win if your company prioritizes eco-friendly practices or reports on ESG goals.

Here’s how used equipment supports your sustainability goals:

- Reduces industrial waste – Keeps quality machines in use instead of being scrapped.

- Lowers carbon emissions – Cuts down on the energy and materials needed to manufacture new equipment.

- Supports a circular economy – Encourages reuse and responsible sourcing.

- Aligns with ESG reporting – Demonstrates a real commitment to environmental responsibility.

Make Your Capital Work Smarter

In 2025, agility matters as much as scale. Used machinery offers both. It lets you deploy capital where it has the most impact, ramp up production fast, and avoid long waits. More than anything, it puts you in control of your operational timeline, not at the mercy of a manufacturer’s backlog.

If you’re ready to make a smarter investment and boost your ROI confidently, contact VX Machinery. We’ll help you find the right used industrial equipment for your operation that delivers high performance at a fraction of the cost.