Category

Manufacturer

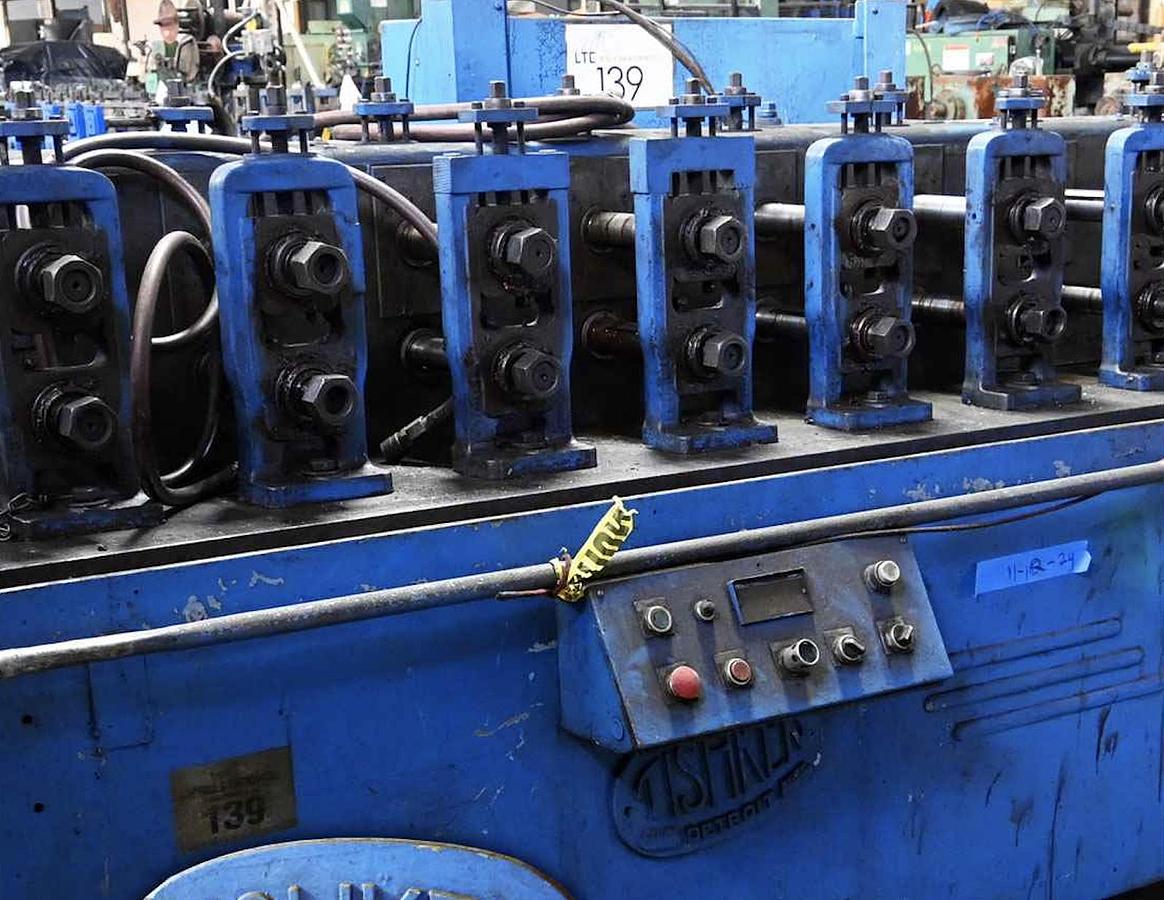

Roll-forming machines transform long metal strips, primarily coiled steel, into specific shapes. Available in our extensive inventory, this machinery employs fixed rollers positioned at multiple stations to bend the metal at room temperature methodically.

Each roller set makes incremental bends, cumulatively achieving the desired cross-sectional shape without altering the material's area. These machines, often functioning at speeds between 30 to 600 feet per minute, are ideal for mass-producing parts or crafting elongated components.

The end products are precisely shaped, requiring minimal finishing, and showcase detailed features. Additionally, roll-forming equipment can handle tasks like material cutting and roll punching.

For top-notch, used roll-forming machinery, explore VX Machinery's selection. Contact our experts now, and let us guide you to the perfect equipment solution for your needs.